Product Attributes

Nominal Size:2"~4"

Temperature Rating:-29°C~121°C(PU)

Service:Standard、Sour gas

Manufacturing standard:API 16C

Product Features

· The elbow body is forged by adopting self-developed controlled simmering and bending process, its geometric dimensions are consistent in full compliance with the requirements of the drawings, and its through-ball performance is greatly improved;

· The innovative process ensures that the height of the inner diameter of the elbow is consistent, and the wall is uniform in thickness everywhere, which has no impact on the fluid flow rate and flow direction, so as to prolong the service life of the product;

· At the same time, the new process ensures that the mechanical properties of the materials after heat treatment are at the leading level in the industry;

· Triple step ball race design increases the wall thickness of vital part and enhances the intensity without increasing swivel joint weight;

· The proven metal frame packing design ensures the sealing reliability;

· Suggestions:The product should be lubricated and maintained regularly (and should also be lubricated before and after each operation). During maintenance, use a manual grease gun for grease injection. Do not use a high-pressure grease gun, and select the recommended grease. Rotate the product 90 degrees after grease injection to go on the second grease injection. Rotate 90 degrees again before the third grease injection, and then rotate 360 degrees to verify the rotation flexibility.

Style 10

| Nominal Size | End Connections | Rated Working Pressure Psi | Dimensions(mm) | Service | |||

L | B | H | |||||

2" | FIG1502 | FXM | 15000/20000 | 279 | 277 | 273 | Standard |

2" | FIG1502 | MXM | 15000/20000 | 279 | 279 | 273 | Standard |

3" | FIG1502 | FXM | 15000 | 369 | 369 | 416 | Standard |

3" | FIG1502 | MXM | 15000 | 369 | 369 | 416 | Standard |

3" | FIG1502 | FXM | 20000 | 516 | 516 | 540 | Standard |

3" | FIG1502 | MXM | 20000 | 516 | 516 | 540 | Standard |

4" | FIG1502 | FXM | 15000 | 516 | 516 | 540 | Standard |

4" | FIG1502 | MXM | 15000 | 516 | 516 | 540 | Standard |

Style 50

Nominal Size | End Connections | Rated Working Pressure Psi | Dimensions(mm) | Service | |||

| L | B | H | |||||

2" | FIG1502 | FXM | 15000/20000 | 140 | 277 | 277 | Standard |

3" | FIG1502 | FXM | 15000 | 202 | 369 | 416 | Standard |

3" | FIG1502 | FXM | 20000 | 258 | 516 | 540 | Standard |

4" | FIG1502 | FXM | 15000 | 247 | 516 | 540 | Standard |

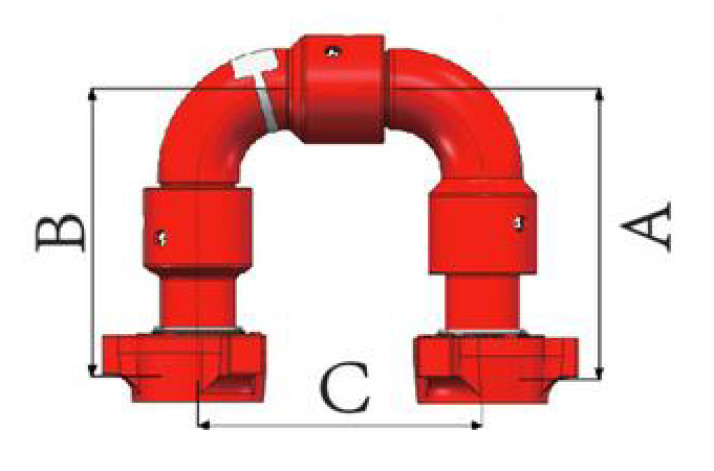

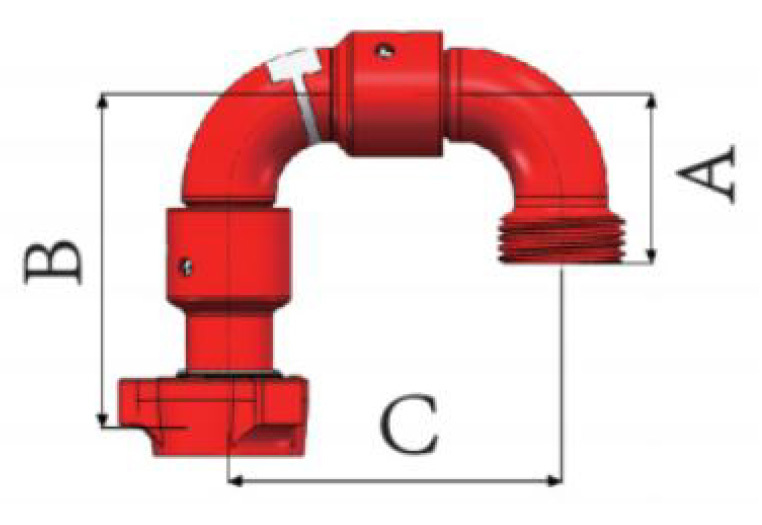

Other Style

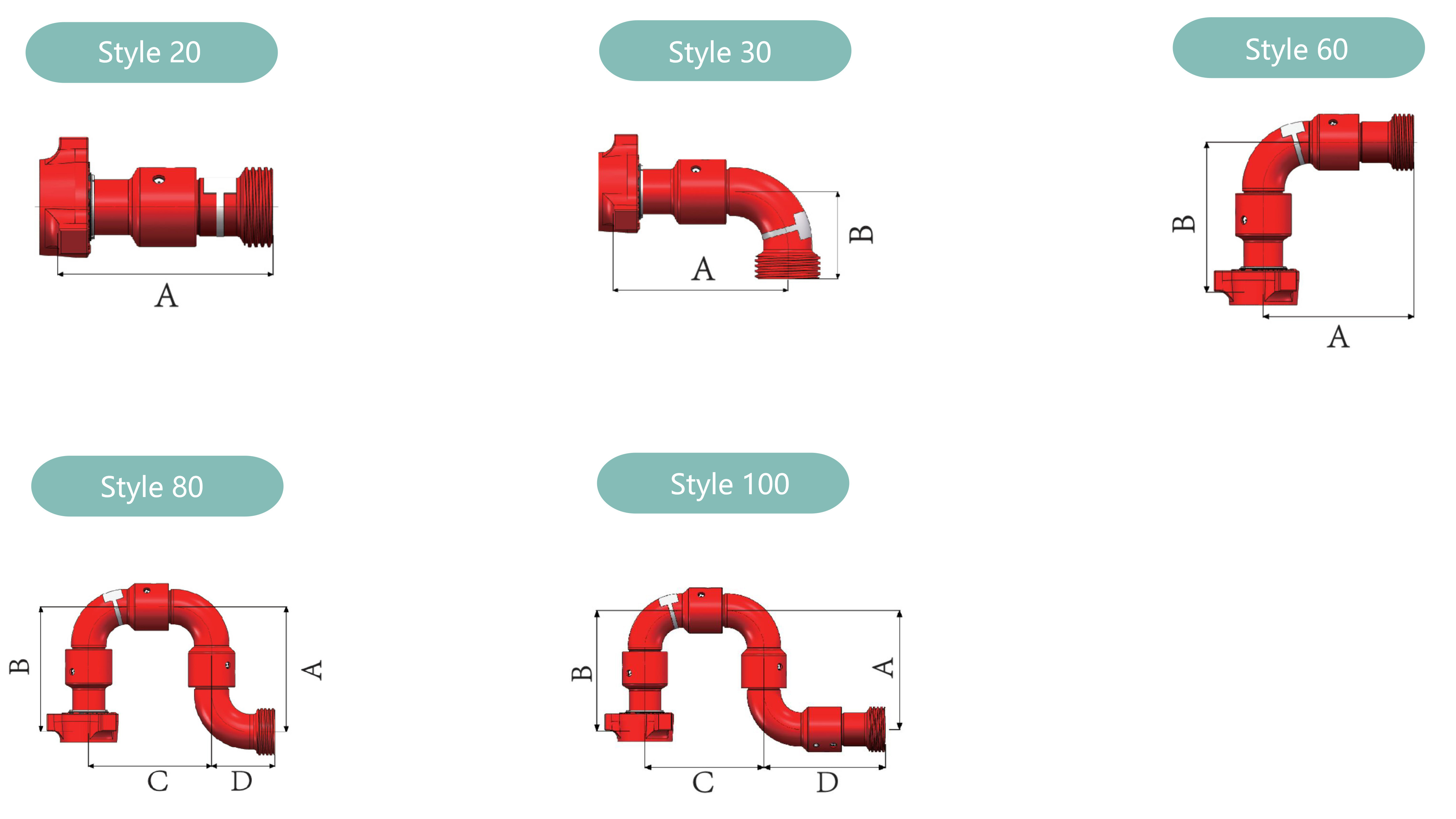

Swivel Joints Repair Kit

| Nominal Size | End Connections | Rated Working Pressure Psi | O Ring I | O Ring II | Packing | Screw | Balls | Ball Plugs | Snap Rings | Service |

2" | FIG1502 | 15000/20000 | 1 | 1 | 1 | 1 | 24 24 24 | 3 | 3 | Standard |

3" | FIG1502 | 15000 | 1 | 1 | 1 | 1 | 34,35,36 | 3 | 3 | Standard |

3" | FIG1502 | 20000 | 1 | 1 | 1 | 1 | 26,27,28 | 3 | 3 | Standard |

4" | FIG1502 | 15000 | 1 | 1 | 1 | 1 | 26,27,28 | 3 | 3 | Standard |

WhatsApp

WhatsApp