Product Attributes

Nominal Size:1"~4"

Temperature Rating:-29°C~121°C(PU)

-46°C~-121°C(LU、Customize)

Service:Standard, Low temeprature, Sour Gas

Manufacturing Standard:API 6A

Product Features

· The valve body is forged by adopting the advanced multi-directional die forging technology, leading in strength and toughness in the industry;

· The plug is coated with nickel-phosphorus alloy, with excellent anti-wear and anti- corrosion properties;

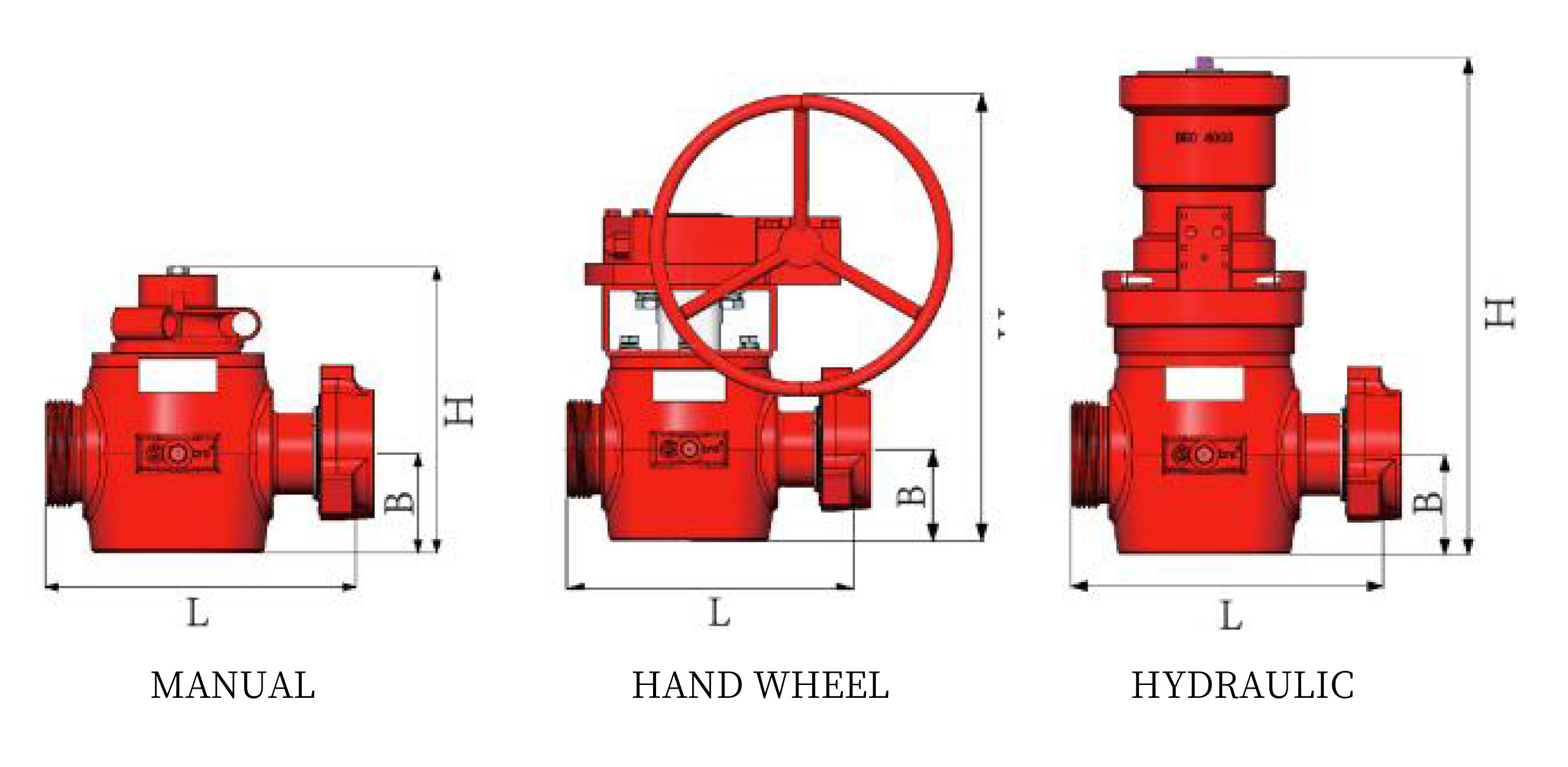

· A variety of opening devices are available;

· The sealing arc plate is specially treated, with excellent performance;

· The seals are developed in cooperation with leading companies in the industry and have exclusive intellectual property rights;

· We can provide customized solutions for our customers.

· Suggestions:The plug valve should be filled with grease after every 3 sections of operation or 3 times of switching; The valve should be flushed clean before grease injection; Each grease injection is completed in 3 rounds: in the first round, an appropriate amount of grease is injected. When residual liquid is observed, the grease injection should be stopped, and the valve should be rotated 90 degrees before the second round of grease injection. When the grease overflow is observed, the grease injection should be stopped and the valve should be rotated 90 degrees before the last round of grease injection is completed. When the grease spillage is observed, the grease injection should be stopped.

Plug Valve Assembly

| Nominal Size | Sealings | End Connections | Rated Working Pressure Mpa/Psi | Actuation | Dimentions(mm) | Service | |||

L | B | H | |||||||

1X2" | Single Seal | FIG1502 | FXM | 105/15000 | Manual | 269 | 61 | 185 | Standard |

1X2" | Dual Seal | FIG1502 | FXM | 105/15000 | Manual | 268 | 61 | 180 | Standard |

2" | Single Seal | FIG1502 | FXM | 105/15000 | Manual | 353 | 88 | 225 | Standard |

2" | Single Seal | FIG1502 | FXM | 105/15000 | Hydraulic | 353 | 88 | 433 | Standard |

2" | Dual Seal | FIG1502 | FXM | 105/15000 | Manual | 358 | 69 | 207 | Standard |

3" | Single Seal | FIG1502 | FXM | 105/15000 | Manual | 432 | 132 | 330 | Standard |

3" | Dual Seal | FIG1502 | FXM | 105/15000 | Manual | 398 | 127 | 366 | Standard |

3" | Dual Seal | FIG1502 | FXM | 105/15000 | Hand Wheel | 398 | 127 | 620 | Standard |

3" | Dual Seal | FIG1502 | FXM | 105/15000 | Hydraulic | 398 | 127 | 633 | Standard |

4" | Single Seal | FIG1502 | FXM | 105/15000 | Manual | 562 | 159 | 488 | Standard |

2" | Single Seal | FIG2002 | FXM | 140/20000 | Manual | 386 | 88 | 266 | Standard |

2" | Single Seal | FIG2002 | FXM | 140/20000 | Hydraulic | 386 | 88 | 433 | Standard |

3" | Dual Seal | FIG2002 | FXM | 140/20000 | Manual | 562 | 159 | 488 | Standard |

3" | Dual Seal | FIG2002 | FXM | 140/20000 | Hand Wheel | 562 | 159 | 771 | Standard |

3" | Dual Seal | FIG2002 | FXM | 140/20000 | Hydraulic | 562 | 159 | 710 | Standard |

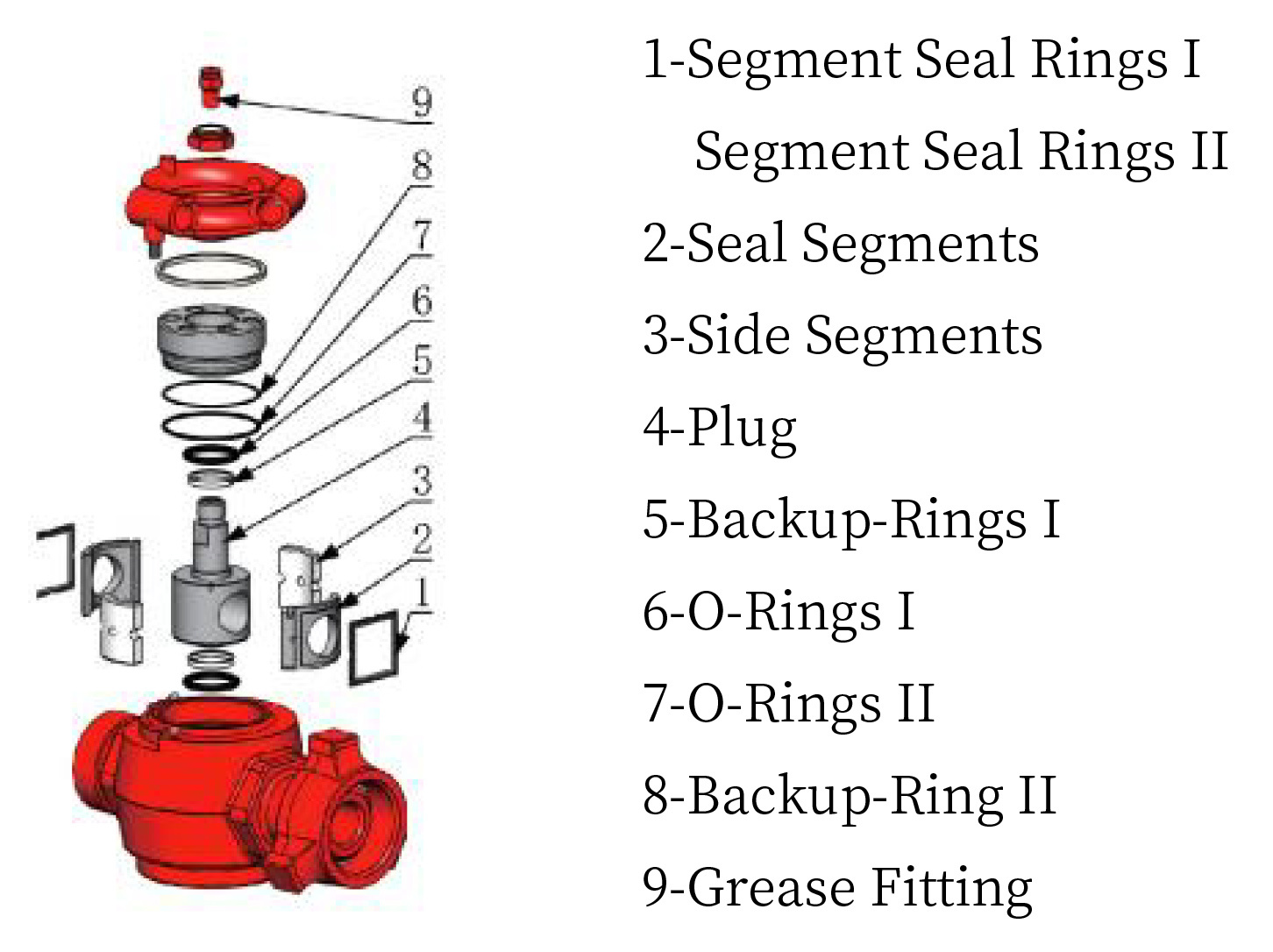

1"~2" Plug Valves Repair Kit

| Item | Descriptions | 1X2"-105 | 1X2"-105 | 2"-105 | 2"-105 | 2"-140 |

1 | Segment Seal Rings I | 2 | 2 | 2 | 2 | 2 |

| Segment Seal Rings II | - | 2 | - | 2 | - | |

2 | Seal Segments | 2 | 2 | 2 | 2 | 2 |

3 | Side Segments | 2 | 2 | 2 | 2 | 2 |

4 | Plug | 1 | 1 | 1 | 1 | 1 |

5 | Backup-Rings I | 2 | 2 | 2 | 2 | 2 |

6 | O-Rings I | 2 | 2 | 2 | 2 | 2 |

7 | O-Rings II | 1 | 1 | 1 | 1 | 1 |

8 | Backup-Ring II | - | - | 1 | - | 1 |

9 | Grease Fitting | 1 | 1 | 1 | 1 | 2 |

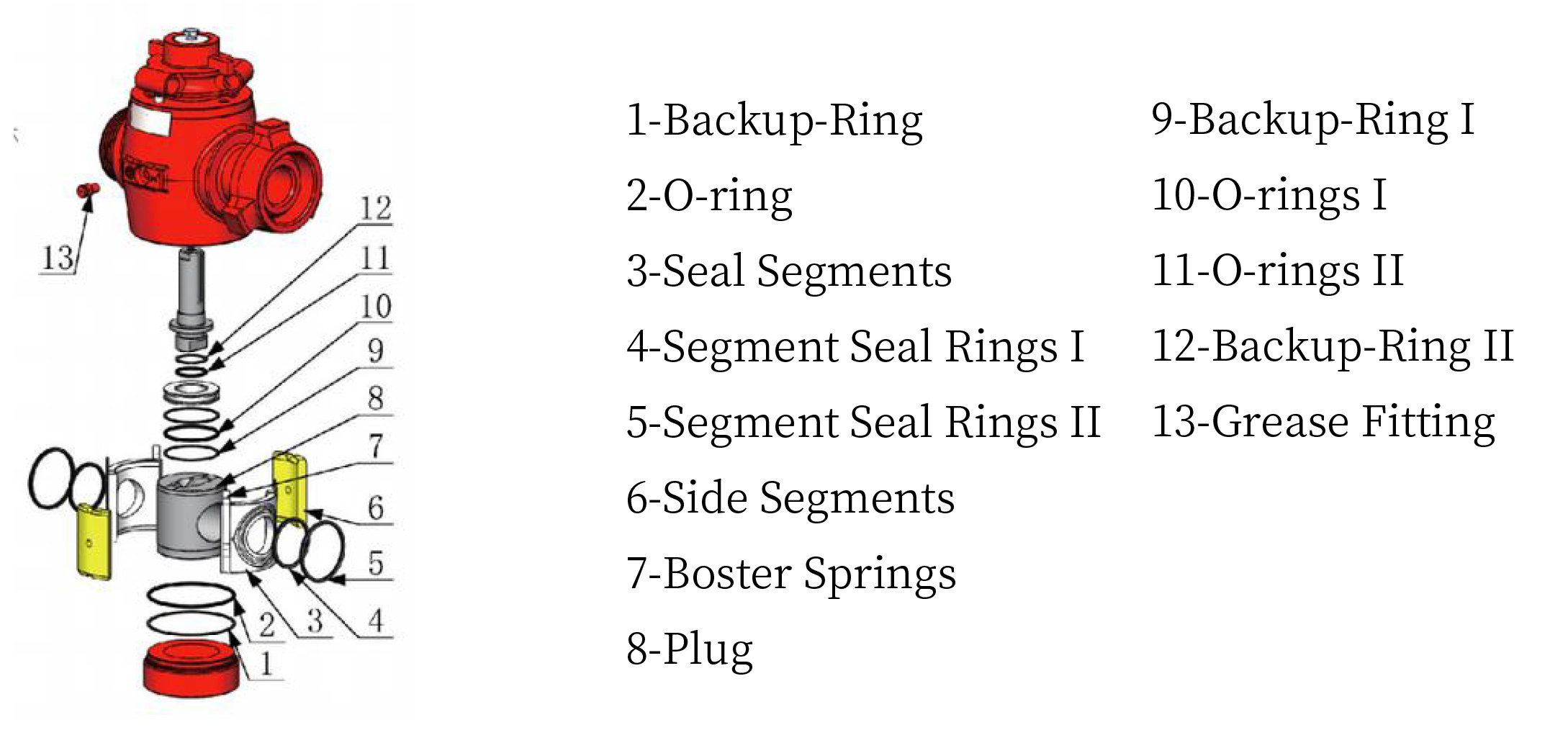

3"~4" Plug Valves Repair Kit

| Item | Descriptions | 3"-105 | 3"-105 | 3"-140 | 4"-105 |

1 | Backup-Ring | 1 | 1 | 1 | 1 |

2 | O-ring | 1 | 1 | 1 | 1 |

3 | Seal Segments | 2 | 2 | 2 | 2 |

4 | Segment Seal Rings I | 2 | 2 | 2 | 2 |

5 | Segment Seal Rings II | - | 2 | 2 | - |

6 | Side Segments | 2 | 2 | 2 | 2 |

7 | Boster Springs | - | 4 | 4 | 4 |

8 | Plug | 1 | 1 | 1 | 1 |

9 | Backup-Ring I | 2 | 2 | 2 | 1 |

10 | O-rings I | 2 | 1 | 1 | 1 |

11 | O-rings II | - | 1 | 1 | 1 |

12 | Backup-RingII | - | 1 | 1 | 1 |

13 | Grease Fitting | 1 | 2 | 2 | 2 |